A Green Alternative

low pressure moulding is an innovative process designed to protect your electronics from environmental factors such as moisture, dust, vibration and handling

low pressure moulding is an innovative process designed to protect your electronics from environmental factors such as moisture, dust, vibration and handling

![]()

The low pressure moulding process allows designers and engineers greater flexibility when designing products when compared to housing electronics in enclosures.

low pressure moulding allows the encapsulation to be the enclosure meaning graphics and surface treatments can be moulded directly onto the surface of the part.

With low pressure moulding, there is no need to compromise.

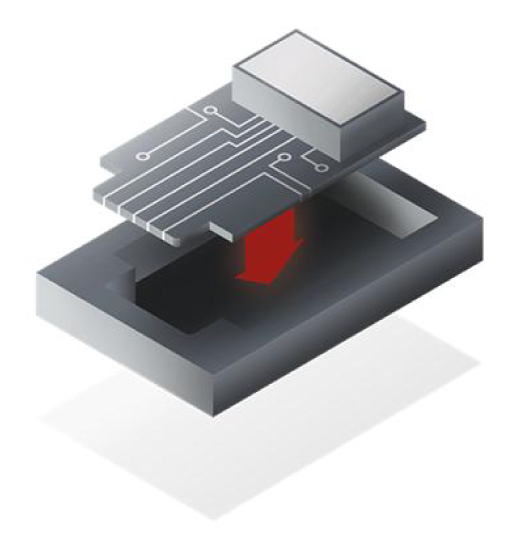

When you replace traditional electronics potting with the low pressure moulding Process you are replacing up to 8 steps with 3 simple steps.

Insert parts directly into the mould set.

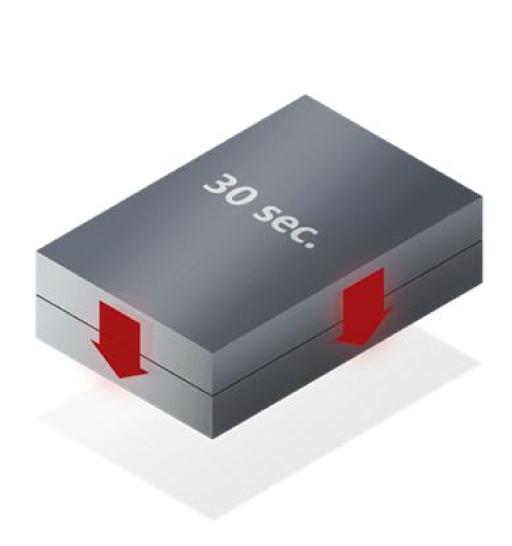

30 sec – 2 min encapsulation process.

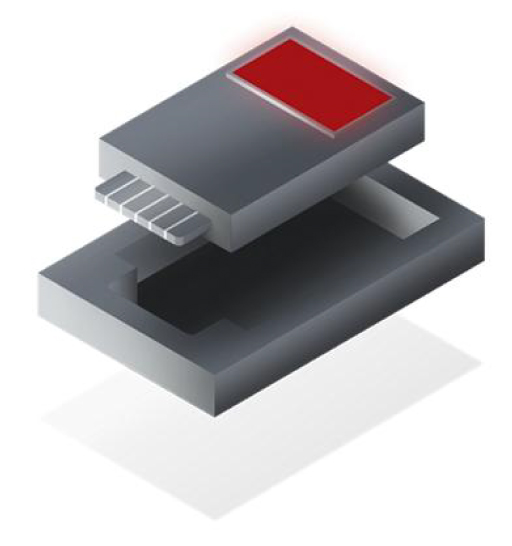

Parts handled immediately after moulding.

LPMS offer low pressure moulding equipment, along with other peripheral requirements such as chillers, dryers and auto-feed systems.

Choose the right Henkel TECHNOMELT material for your application

Low Pressure Moulded products extend across a variety of applications catering for a diverse array of industry sectors.

Let us assess your product and see if Low Pressure Moulding is the solution you’ve been looking for.